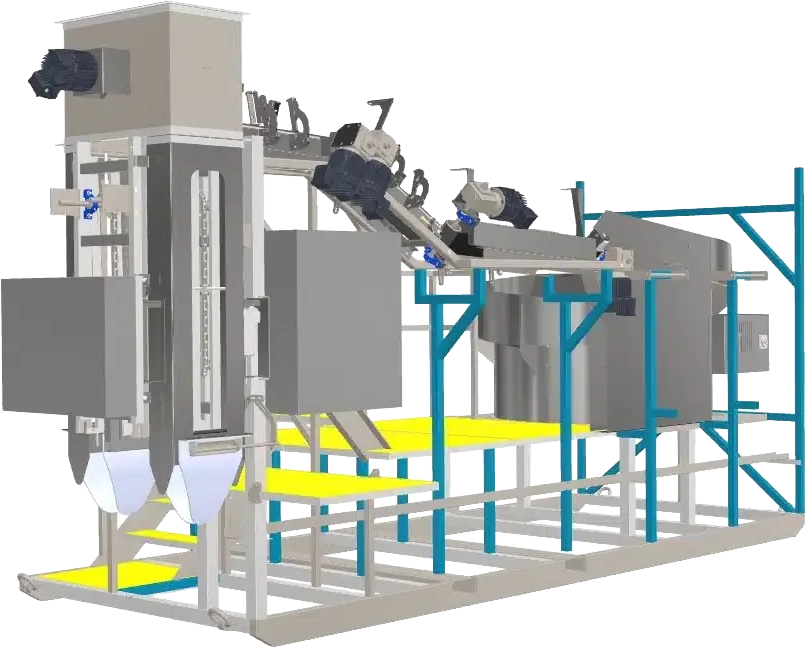

Technical specifications for North America’s first automated firewood packaging machine, engineered for industrial performance and operational efficiency.

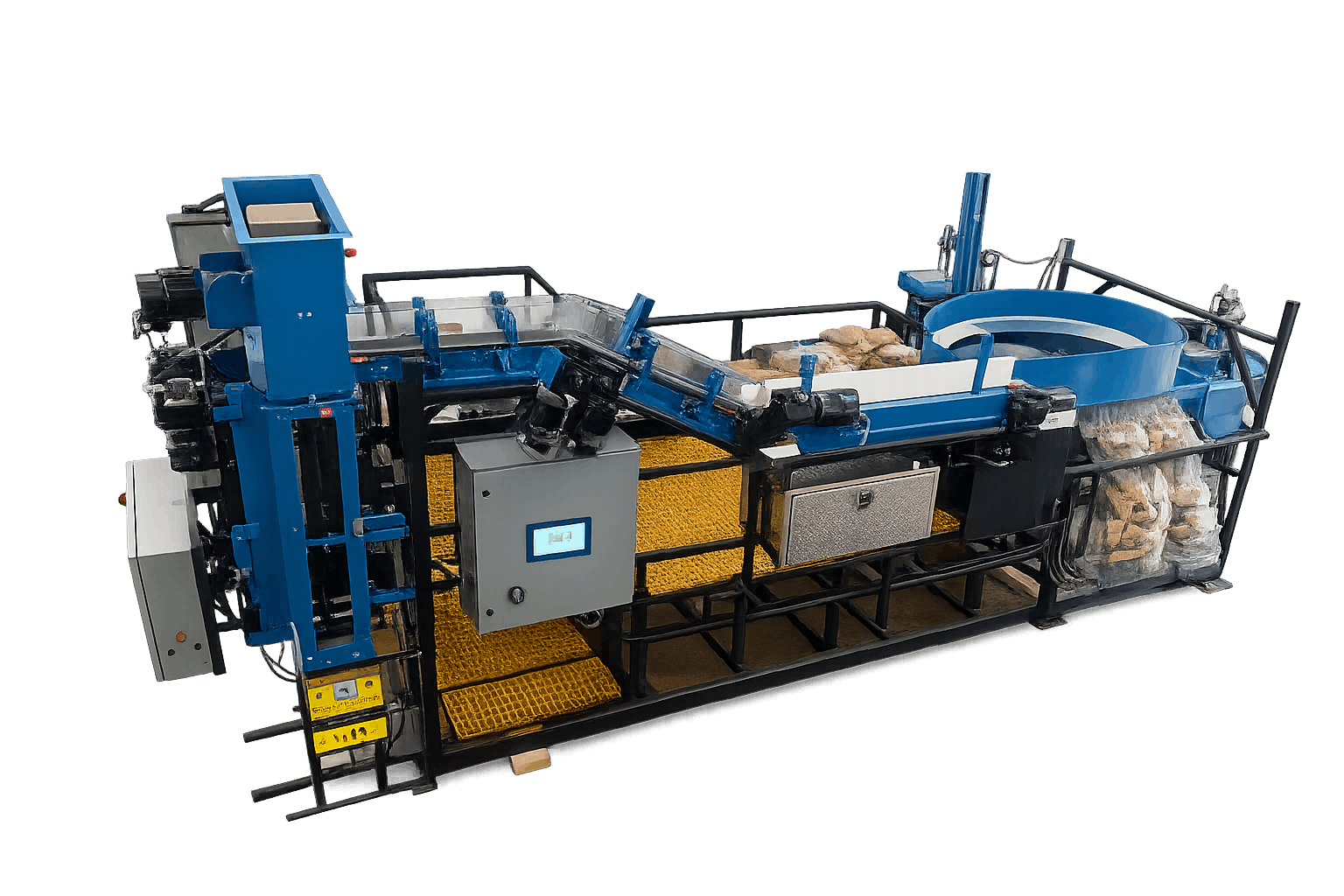

This product data sheet provides an overview of the design, capabilities, and operational requirements of the AND “Y” Knot Firewood Packaging Machine. Built specifically for firewood operations, the system is engineered to reduce labor, streamline workflow, and deliver consistent packaging output in demanding environments.

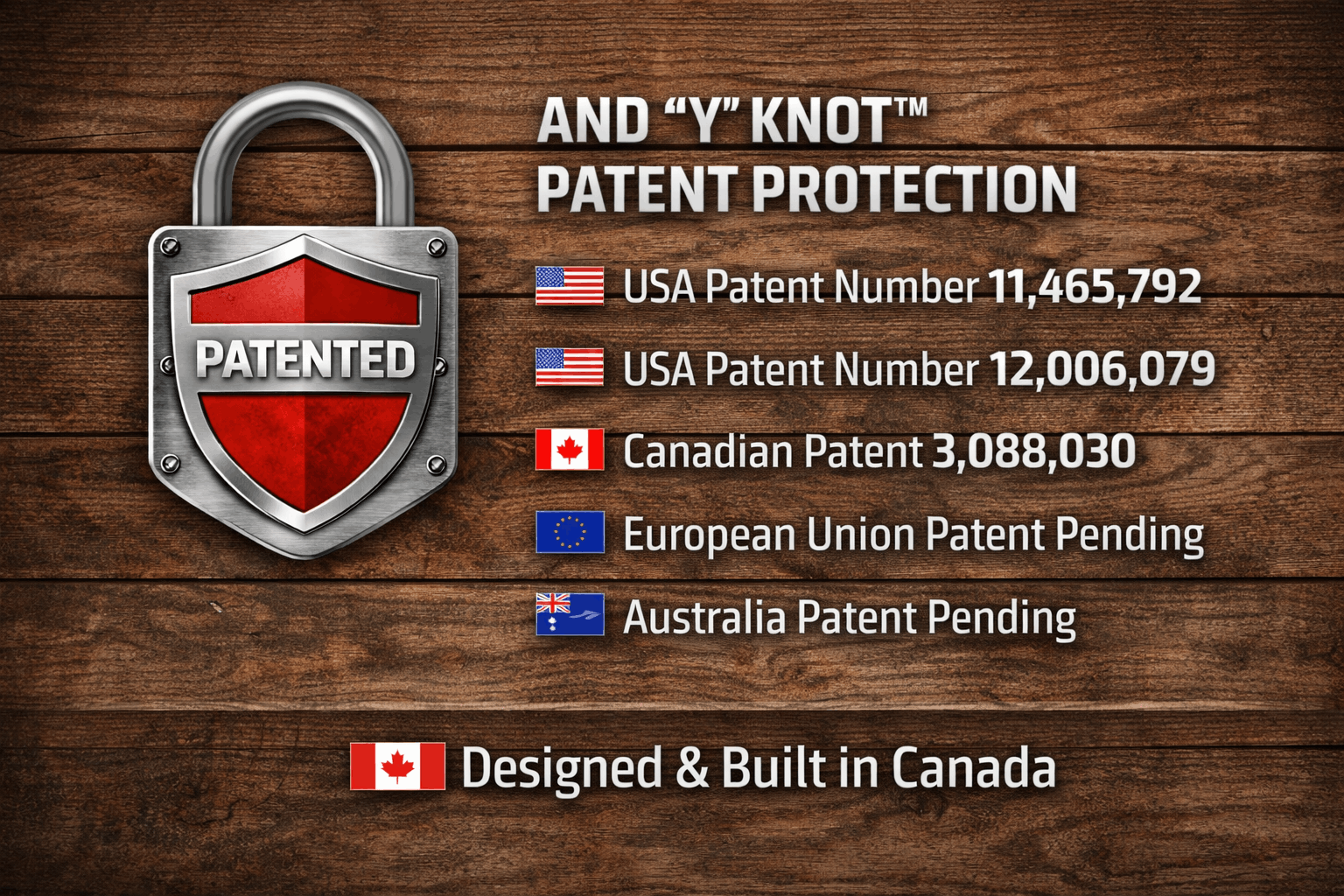

The AND “Y” Knot Firewood Packaging Machine is a purpose-built automated firewood packaging solution, designed and manufactured in North America to meet the operational realities of modern firewood producers.

Unlike repurposed or mechanized systems, AND “Y” Knot delivers true automation focused on packaging efficiency, reduced manual handling, and scalable production—without unnecessary complexity.

The And “Y” Knot Firewood Packaging Machine reduces packaging time and handling requirements associated with firewood packaging and reduces lead time and storage needs of packaged product prior to prime selling seasons. Traditional manual firewood packaging is a physically taxing process that makes it difficult to retain employees, because 87% of the time preparing firewood for client use is spent packaging.

A single person is capable of making 1 bag/package in approximately 2 minutes. The machine is capable of making 3-4 bags/packages in 1 minute.

- 4 cubic meter capacity — approx. 1 hour of material

- Electrically driven, sensor controlled intake

- Sensor-controlled smooth material flow

- Automatically aligns firewood pieces for next stage

- Continuous rotating conveyor maintains flow train

- Designed to reduce jams and manual intervention

- High speed forward/reverse conveyor

- Automatic unjamming built in

- Continuously running, adjustable speed

- 6 ft rotating disc to remove debris

- 8 ft outfeed conveyor to the turntable

- Elevated circular feed chain

- Adjustable profiler for continuous single-file feed

- Sensor-controlled positive-grip start/stop conveyor

- Upward motion conveyor for consistent feeding

High-speed, fully automated packaging designed to reduce labor, control costs, and scale production—without adding complexity.

Designed for on-demand production, AND “Y” Knot helps reduce inventory carrying costs while maintaining consistent packaging quality. Fully automated electronic controls, remote adjustability, and dual bagging heads maximize throughput while minimizing operator effort. The ergonomically engineered system reduces physical strain, requires very little training, and integrates advanced safety features to protect operators and equipment.

Built with robust industrial construction and a simple, low-maintenance design, AND “Y” Knot delivers reliable performance day after day—making automation practical, scalable, and profitable.

| Bag per Year | Years ROI | |

|---|---|---|

| $0.40 per bag | $0.50 per bag | |

| 40,000 | 11.526 | 9.25 |

| 50,000 | 9.25 | 7.40 |

| 60,000 | 7.70 | 6.16 |

| 70,000 | 6.60 | 5.28 |

| 80,000 | 5.78 | 4.62 |

| 90,000 | 5.13 | 4.11 |

| 100,000 | 4.62 | 3.70 |

| 110,000 | 4.20 | 3.36 |

| 120,000 | 3.85 | 3.08 |

| 150,000 | 3.08 | 2.46 |

| 175,000 | 2.64 | 2.11 |

| 200,000 | 2.31 | 1.85 |

| 225,000 | 2.05 | 1.64 |

| 250,000 | 1.85 | 1.48 |

| 275,000 | 1.68 | 1.35 |

| 300,000 | 1.54 | 1.23 |

| 350,000 | 1.32 | 1.05 |

| 400,000 | 1.15 | 0.93 |

22 ft (264”) Long

8 ft (96”) Wide

10 ft (120”) Tall

6000 lbs (2721 kg)

125/250 V (30Amps) Single Phase

If you’re looking to modernize your firewood packaging operation and reduce labor dependency, AND “Y” Knot delivers automation designed specifically for your industry.